The traditional woodworking lathe is slow, the operator cannot leave the machine, the operation requirements are high, the stability of the lathe is poor and complicated; the operator has a long learning time, is prone to errors, the defective rate is high, the processing speed is slow, the processing quality is unstable, and the surface of the processed workpiece is rough It directly affects the difficulty of the next grinding process, and also makes the operation more labor-intensive and difficult. When encountering local hard parts of the processed part, it is easy to cause the safety of the processed part to break and hurt people.

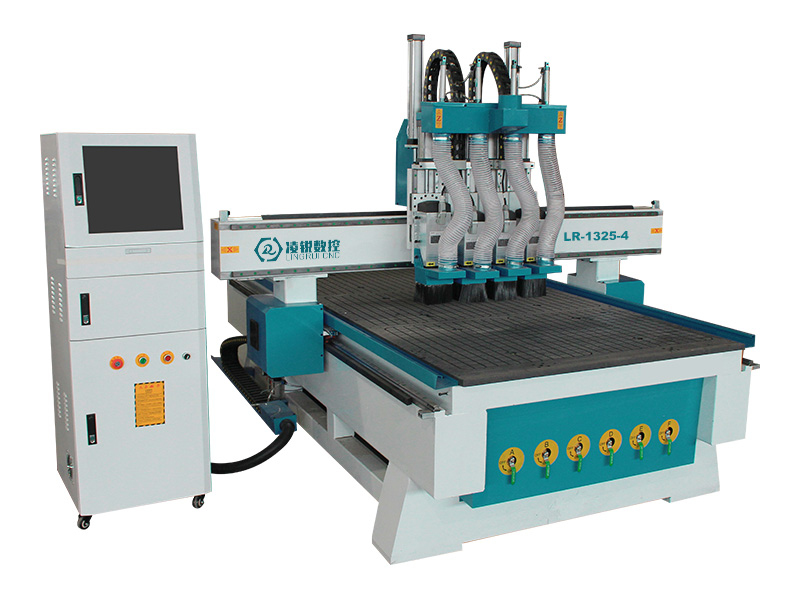

Lingrui automatic CNC woodworking lathes are suitable for processing long and thin woods as well as coarse woods, and have the characteristics of a wide range of softness and hardness of processing materials. After processing, the surface of the workpiece is brighter than that of existing woodworking lathes; including base and bed Body, program control system, headstock, center plate, tool post movement system, tailstock, machine tool lubrication system, characterized by: program control system, headstock, tailstock, tool post movement system, machine tool lubrication system installed on the bed, The body and the base are connected as a whole; it is mainly used for wood processing.

CNC woodworking lathes are not only capable of processing completely symmetrical wooden rod parts, they are also capable of making heterosexual parts that are difficult to process, such as European-style chair legs, special-shaped crafts, and so on.

It takes about 10 minutes to process a European-style chair leg using a woodworking engraving machine, while it only takes about 2 minutes to use a fully automatic CNC woodworking lathe, which also includes rough grinding. Does this processing efficiency greatly improve the processing efficiency and quality of the components?

Compared with traditional woodworking lathes, what are the advantages of fully automatic CNC woodworking lathes?

1. Strong adaptability to processing objects.

Because when changing the machining parts on the CNC woodworking lathe, you only need to reprogram the program to realize the processing of the new parts. Unlike traditional woodworking lathes, there is no need to manufacture and replace many tools, fixtures and measuring tools, and there is no need to re-adjust the lathe. . Therefore, CNC woodworking lathes can quickly transform from processing one part to processing another, which provides great convenience for single parts, small batches, and trial production of new products, which not only shortens the production preparation cycle, but also saves The cost of a large number of tools.

2. Automated operation mode.

Compared with traditional lathes, the degree of automation of CNC woodworking machine tools has been greatly improved. CNC woodworking lathes do not require workers to operate the equipment all the time, but only use a programming language to compile the content of the drawings into the computer of the CNC lathe before processing. The computer will actively analyze and direct the operation of the equipment through the central processing unit. Such a CNC machine tool is a great relief for manpower and greatly improves the accuracy of delivery.

3. High processing precision.

CNC woodworking lathes are processed by instructions given in digital form. Because the pulse equivalent of current CNC woodworking devices can generally reach 0.001 mm, and the backlash of the feed transmission chain and the lead screw pitch error can be processed by the CNC device Compensation, so the CNC woodworking lathe can achieve higher machining accuracy and quality stability, which is determined by the necessary measures in the structure design of the CNC lathe and the characteristics of electromechanical integration. The first is the introduction of the ball screw nut structure, various clearance elimination structures, etc., to reduce the error of the mechanical transmission as much as possible, and the second is the use of software precision compensation technology to further reduce the mechanical error; the third is the use of Program control processing reduces the influence of human factors on processing accuracy. These measures not only ensure the higher processing accuracy of the CNC woodworking lathe, but also ensure the stability of the higher processing quality.

4. Good processing quality.

Compared with traditional CNC woodworking lathes, CNC woodworking lathes are suitable for processing slender woods as well as coarse woods, and have the characteristics of a wide range of softness and hardness of the processed materials. The surface of the workpiece after processing is brighter than that of traditional woodworking lathes.

5. One machine is more productive, and it is imperative to improve work efficiency.

The traditional lathe intelligently processes one product at a time during processing, while the dual-axis and double-cutter CNC woodworking lathe in the CNC woodworking lathe can process two identical products at the same time. Simple operation, convenient drawing, simple and easy to understand, one-key conversion of product styles, and no professional knowledge personnel can operate it with a little training. In addition, the fully automated CNC woodworking lathe can operate 2-3 units at the same time by one person, which greatly improves the processing efficiency, saves labor and money, and brings good economic benefits. The time required for parts processing includes two parts: maneuvering time and auxiliary time. CNC lathes can effectively reduce these two parts of time, so the processing productivity is much higher than that of ordinary woodworking lathes. The range of spindle speed and feed rate of CNC lathe is larger than that of ordinary lathe, and the most suitable cutting amount can be selected for each process. At the same time, the good structural rigidity also allows the CNC woodworking lathe to perform powerful cutting with large cutting amount, effectively saving The maneuver time. The rapid movement and positioning of the moving parts of the CNC lathe adopts acceleration and deceleration measures, so a high idle stroke movement speed is selected, and the time consumed in fast forward, fast rewind and positioning is much less than that of a general lathe. The machining accuracy of CNC woodworking lathes is relatively stable. Generally, only the first part inspection and the sampling inspection of key dimensions between the working procedures are performed, which can reduce the time of downtime inspection. When using a CNC woodworking lathe with a tool magazine and an automatic tool changer, the continuous processing of multiple procedures is realized on one lathe, which reduces the turnaround time of semi-finished products and improves production efficiency more significantly.

Machine bed and frame is welded with 12mm thickness steel tubes. heavy-duty machine bed.

Machine bed and frame is welded with 12mm thickness steel tubes. heavy-duty machine bed.

Machine bed and frame is welded with 12mm thickness steel tubes. heavy-duty machine bed.

Machine bed and frame is welded with 12mm thickness steel tubes. heavy-duty machine bed.